Cooling Me Softly: Matthieu One of Our Energy Efficiency Specialists

Tested and Approved: Synergy Efficiency Solutions had the opportunity to assess the performance of a combined Hot Water/Cooling System during an Energy Audit. The full story can be accessed by clicking “Read more” below

Audit Tale #1 How detailed: Chiller & Heat Pump Combination

As an energy efficiency specialist in a tropical country, and more particularly in Indonesia, most of my work focuses on cooling systems. This is logical because when it is 30C degrees plus outside, you do not want it to be 30 degrees plus inside. Big, small, split, centralized, air-cooled, water-cooled, ducted, duct-free, there are as many systems and configurations as there are islands in the archipelago. In June I had the opportunity to carry out a Level 1 Energy Audit at a famous hotel in Yogyakarta. The 50 year old hotel, which went under renovation 5 years ago, completely refurbished and replaced its cooling and hot water system. The purpose of this audit, among other things, was to look for energy savings opportunities, but also to observe the new systems installed with the renovation and analyze their operations and performance.

When auditing cooling and hot water systems I typically expect to find corroded pipes, old and tattered pieces of insulation and its common for me to even find the engineering staff drying their hand washed clothing on the condensing units blowing off heat. So you can imagine my good surprise when I stepped into the utility room and was tasked to assess a brand new installation.

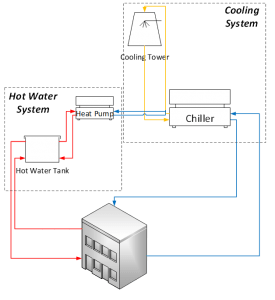

The Figure below describes the system installed at the Hotel (pumps and valves not represented)

The system installed uses a centrifugal chiller for the cooling system and a screw chiller heat pump for the hot water system. All the machines installed were less than 5 years old and in good condition. The interconnection between the two systems (hot water and cooling) was the inventive feature that really caught my Attention.

Cooling System

The cooling system runs with one centrifugal chiller to produce the cooling required by the guest rooms and other areas in the hotel;

The second chiller kicks in only in the case of high occupancy or use of exhibitions and ballrooms;

On the evaporator side, the chilled water is being supplied to the different Air Handling Units in the hotel, and flows back to the chiller at a high temperature;

On the condenser side, the water is being supplied to the Cooling Towers and flows back to the chiller at a low temperature.

Hot Water System

- The hot water system runs with one heat pump to produce the hot water required by the guest rooms, restaurants and other areas of the hotel;

- On the evatorator side, the chilled water is being supplied to the water tank before being distributed to the different hotel water fixtures through a ring main. Water flowing back from the hotel goes thorugh the hot water tank before passing back through the heat jump to be heated.

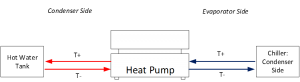

Both chillers and heat pumps work based on the vapor-compression cycle. The heat absorbed on one side (evaporator) is rejected on the other (condenser).

The difficult part of an efficient heating or cooling system is how to manage the “undesired” energy. For the chiller, it corresponds to the heat on the condenser side, while for the heat pump, it corresponds to the heat absorbed on the evaporator side.

A chiller/heat pump does not “produce” or “create” heat, but displace it. With the heat pump, the amount of heat added to the water to increase its temperature (hot water production) has to be absorbed somewhere else. If the both sides are not well balanced, then the unit will work harder to compensate and consume more energy.

To put it simply:

– The more heat is rejected on the condenser side, the more efficient the chiller will be in order to produce cooling;

– The more heat is absorbed on the evaporator side, the more efficient the heat pump will be in order to produce hot water

The smart idea behind the combined system installed here resides in the decision to absorb the undesired energy of the hot water system out of the cooling system undesired energy. With this configuration, the hot water system evaporator side cools down the condenser side of the cooling system, killing two birds with one stone. As a consequence, the condensed water flowing through the cooling towers and back to the chiller has a lower temperature without additional energy consumption! This configuration increases the efficiency of the chiller and allows reducing the energy consumption of the cooling Towers.

There are a few good points to this configuration from what I observed:

– The inter connection between the hot water and the cooling system allows for the normally wasted energy from one side (hot water system) to be reused on the other side (cooling system);

– This configuration is working even better due to the proximity of the two systems, located in the same room, a few meters from each other.

Similar configurations and other alternatives to combine both the cooling and hot water systems have been in practice for many years, but seeing it installed and performing well proves the feasibility of this solution. This configuration does not require particular additional investment or design while offering interesting energy savings opportunities.

There are always ways to improve a system performance further, since no system is ever going to be perfect. Nevertheless, this configuration showed an interesting and well thought through alternative to efficiently produce both the cooling and heating required by the building, with the two systems operating hand in hand.

Author: Matthieu Caille, Energy Efficient Specialist at SES